July 2021

Result from coordinator TUe.

Result has been achieved on 15 June 2021 in month 13 of the project (results documented in Work Package 5 of the planned result: Technical feasibility of lignin based fuels in ship engines).

TU/e is member of the Engine Combustion Network (ECN) that is an international collaboration among experimental and computational researchers in engine combustion, with the objective of creating a well documented library of experiments as benchmarks for simulations. These experiments are designed with well established parameters, to make them replicable, in simulations as well. Spray A is the standard with the most experimental results. Spray C and D are less common, but are more important for this project, being designed for applications (slightly) closer to Marine applications (larger nozzles typical for heavy duty engines). Validation of the approach for well-defined test cases is an important step towards the final goal, modelling the full engine.

- Objective: To create reliable models of standard Spray A to be applied to Spray C and D, more similar to Marine Nozzles applied in WinGD Constant Volume Chamber.

- Research: TUe has applied the tabulated combustion method called FGM to ECN standard cases, implementing and using it in the open source software OpenFOAM.

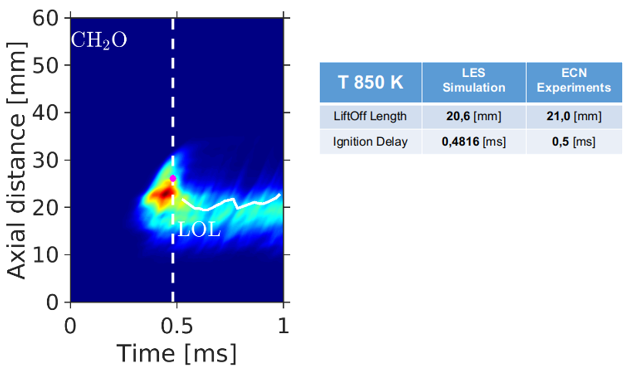

- Result: There have been very good simulations results, in particular for one of the oxidizer temperatures analyzed: simulations output overlap almost perfectly experimental data.

- What will it be used for: This result will be the base to create a reliable Spray C and D model and finally for a Marine type nozzle.

- Impact: This result confirms that the FGM combustion model can produce very accurate spray combustion results, applying detailed chemistry with limited resources. This gives confidence for the use the approach in the engine model we are going to work on in the future to test the lignin-based fuel.

Above you can see a LES simulation of spray A. Shown are the droplet diameter and the mixture fraction as function of time.

Above you can see a LES simulation of spray A. Shown are the droplet diameter and the a contour of the progress variable (representing the flame) colored by temperature.

A so-called IXT plot. Radially integrated CH2O field as function of time. Illustrates the occurrence of Low Temperature combustion prior to the main flame. The Lift-off-Length (LOL, defined by the OH mass fraction) is indicated by the solid (horizontal) white line. The dotted vertical line indicates the experimentally determined ignition delay.